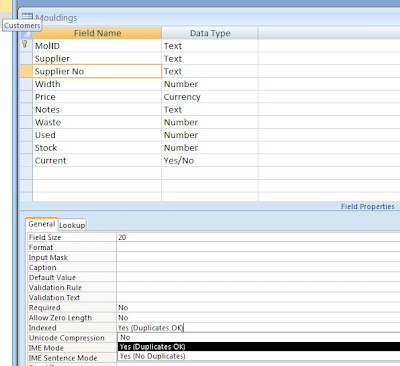

Now you've only got to think a moment to realise that trying to keep track of moulding stock with a computer program is fraught to say the least.

On the face of it all the program has to do is work out how much moulding it's going to use for a particular job (plus, perhaps, a percentage waste), and take that off the existing stock figure - simples?!

Well, no, actually.

First of all the database of mouldings has to be updated each time more stock comes in.

Then how do you account for warped or damaged moulding? You could unwrap each length and carefully inspect it, but, unless you wrap it up again, you're asking for the unwrapped moulding to be scraped, scratched or worse.

Lastly, the moulding could be from different batches which are not compatible. Try telling the program that!

Of course it would be possible to write the program to take account of all the problems, but I think that it would make things so complex that no one would bother trying to keep the stock figure correct.

So, the Wessex Programs tries to keep the stock control simple, keeping it is easy to understand. But this does mean that common-sense also has to be used to keep the figures adjusted and up to date. With a little application you'll find that the moulding stock part of the program is more of a help than a hindrance. I'll give two instances

- When you give a price the program looks at the moulding stock figure. If that figure is less than the low stock threshold (I have mine set at 3 Mt - roughly 1 length) then a warning is flashed up, so you know to check the actual stock before committing to a completion date.

- If you are ordering from a particular supplier you can look at the "Low Stock" list in the mouldings database. This shown by supplier so you can see other mouldings to order, perhaps making up a carriage paid order rather than a piecemeal series of orders.

Well, surprisingly close, and what was even better - after the upto date figures had been entered the total value of the stock was there already worked out saving hours with a pen and calculator.