Transcript of talk given to Wessex Branch of FATG by Stephen Hible GCF., 28/06/11.

Why is Frame Pricing so important?

I hope I don’t disappoint too many of you if I reveal the ending of this talk now, - there is no magic formula for pricing, you won’t go away with the problem solved. But, I hope you’ll go away with some ideas and a renewed confidence in setting your pricing strategy.

This coming September will mark my 35th year in the framing industry, since I got my Fine Art degree I’ve had no other job. But I still get up in the morning and look forward to the day’s work (most of the time!) I’m sure, however long you’ve been a framer, you feel the same too. We aren’t framers because we want to make money. We’re framers because we love the job. That means that perhaps we’re prepared to lower our price for a job because we really want to do it. In turn, that means our margins are dragged down, so we make even less money. So, if we haven’t set our prices at a sufficiently generous level in the first place, we’re going to enter that downward spiral which is very difficult to get out of. I’ve heard of a framer charging £50 to frame a Rugby shirt and still being prepared to reduce the price if the customer was unsure!

The effect of increasing versus decreasing prices is very marked. As the maths shows us the only sensible way to go is to increase prices. General discounting is a complete no-no, we’ll never compete with Ikea or Wilkinson’s and I, for one, wouldn’t want to.

Note the ”number sold” line which increases & decreases with the price changes.

Effect of price increase/decrease

| ||||

+10%

|

+100%

|

-10%

| ||

Sell for

|

100

|

110

|

200

|

90

|

Cost of manufacture

|

80

|

80

|

80

|

80

|

Profit

|

20

|

30

|

120

|

10

|

Number sold

|

250

|

225

|

62

|

275

|

Total Profit

|

5000

|

6750

|

7440

|

2750

|

% change

|

+35.00%

|

+48.80%

|

-45.00%

| |

“When you put up prices, the clients you lose will be mean, penny-pinching pondlife. Buying on price, they will be disloyal clients from hell, making unreasonable demands yet not valuing your service. You do not need them. I for one say Good riddance!”

Source – ABT, April 2011

|

Another effect of increasing prices is that the better materials can produce the profit without being marked up as much. For example - a piece of specialist glass might cost you £10, doubling up will give you another £10, but standard glass might be £3 for the same size – double up and you’ve still only made £3. I know which I’d rather have!

Because you can have more time with the customer you have more time to show the possibilities. I’m not talking “hard-sell” – specialist glass, rag mountboard & stylish mouldings, when presented properly, all sell themselves.

Obviously your prices must be based on the economics of your business – your hourly rate. This is going to be more if you are a high-street business with large overheads, as opposed to someone with a workshop at home. However, a high-street business is going to get a lot more work than someone hidden away, so it is more likely to fill all the available hours with productive work (making frames and talking to customers).

Working out how long it takes to do a job, like cutting a mount or joining a frame, and then applying the hourly rate is also not as easy as it would first seem. Sometimes the job just “flows” other times you have to “fight” the job all the way. So, I always maintain that “broad brush strokes” are required when setting down the individual costs, some you’ll win, a few you’ll lose – make sure it’s that way round.

How do you price your frames? That’s a rhetorical question and I know there are many answers. I’ve even had a framer tell me that he doesn’t give a price right away, but rings the customer in the evening after he’s worked out all the quantities etc.! I’ve also heard of a framer who looked at peoples shoes – the more expensive the shoe the more expensive the frame!

In years gone-by most would have said “A two-way table”. That was fine 20 years ago. Today people have different expectations. Now, customers expect to see computers in businesses. Computers are “trusted” (If the computer has produced the price it must be right. You can’t argue with a computer).

This is good, because working out the cost of framing is a repetitive calculation. You just need the dimensions, type of moulding, glass, mount and sundries – add the individual costs up – add on VAT and there’s your price. It’s the type of work a computer loves, in fact I’d say they are as happy as a pig in .... muck!

But as with all things “the devil is in the detail”. We need to allow for wastage, for the mitres. It would be good to have a warning if we need oversized mountboard or glass, or if a moulding is out of stock. It would be even better if you could just show the things you actually do. For instance you might want to list “V Grooves” under mounts, but not “Deep Bevel”, or “Football Shirts” but not “Medals”.

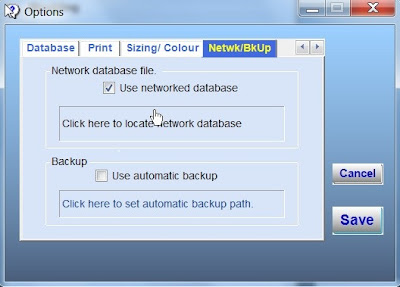

It’s possible to do all that (and more) but the trick is to make the layout of the program logical, simple, with as few buttons to click as possible. After all you need to spend your time with your customer, not with the computer. You are the reason the customer is there, not your computer. There are many programs out there for framers, but sadly most have been designed by someone who has never made a frame in their life.

Another requirement for a pricing program is - that the way it works out the price should be reasonably easy to understand, so you can set it to the prices you want to charge. That is going to be different if you are in Merthyr Tydfil to if you are working in an affluent home counties town. I believe that it is one of our responsibilities as business people to set the prices we charge, not abdicate that responsibility to a computer program. As a writer of one of those programs I can’t and I shouldn’t tell you what prices you should charge – that’s for you and your business. But I can make sure that those prices are easy and quick to issue, as well as being consistent and that the parameters used to work out the price are accessible and transparent.

Another thing that is just nuts to a computer is to take that price it’s just issued and record it as a job in a database together with customer details and so on. This means that, whilst you may want to work on paper tickets as the job goes through the workshop, – you don’t need the store the paper for if the customer comes back next year and wants the same frame/mount etc. (also much easier on a computer to find, than sorting through a pile of crumbling work tickets). Once the jobs are in the database it’s so easy to produce a list of what you should be doing and in what order. No more jobs that have been put away “safely”, only to be forgotten about until the customer comes back!

So, I hope I’m convincing you that a computerised system is the way to go, and of course I hope you are all going to buy “Wessex Professional” which is the program I have on my computer here. However when you do look at the various systems ask yourself –

1. Does the program look professional? For instance the IPhone just oozes “professional” before you’ve even touched it

2. Is it easy & straightforward to use? Could anyone use it to issue a price

3. Is it understandable how to change the parameters to reflect your prices?

4. Are you going to be paying for features you don’t need? For instance, you probably won’t need access to obscure German supplier pricelists, or the ability to run the program in Swedish!5. Will the system the program imposes on you fit in with the way you run your business? By that I mean – if you haven’t used a computerised system before you’ll be going from something with a high human input to a system with a high machine input which will impose certain ways of doing things. This is where a program written by someone who has actually made a frame stands out.

6. Is it going to be easy to get support? Even with all the help files (& Wessex Professional comes with a comprehensive set of “How To” videos as well as the usual Help files) you are still likely to have questions and problems to be sorted out as you come to grips with your new “toy”.

7. Lastly, will the system cope with an unforeseen type of job? - Wessex Professional has the ability to enter any moulding that is not in its database as well as any Extra Cost (with or without Vat).

To finish up talking (before I demonstrate the program to those who are interested) I have to thank a whole bunch of framers who I’ve met and who use Wessex Professional. Their input has shaped the development of the program – for instance the ability to issue prices in whole pounds came from a customer request. They have also helped iron out errors and bugs (there are something like 12,000 lines of program code) as well as making suggestions so the program “flows” more easily.

Thanks for listening.

© S. T. Hible, 2011

Transcript of talk given to Wessex Branch of FATG by Stephen Hible GCF., 28/06/11.